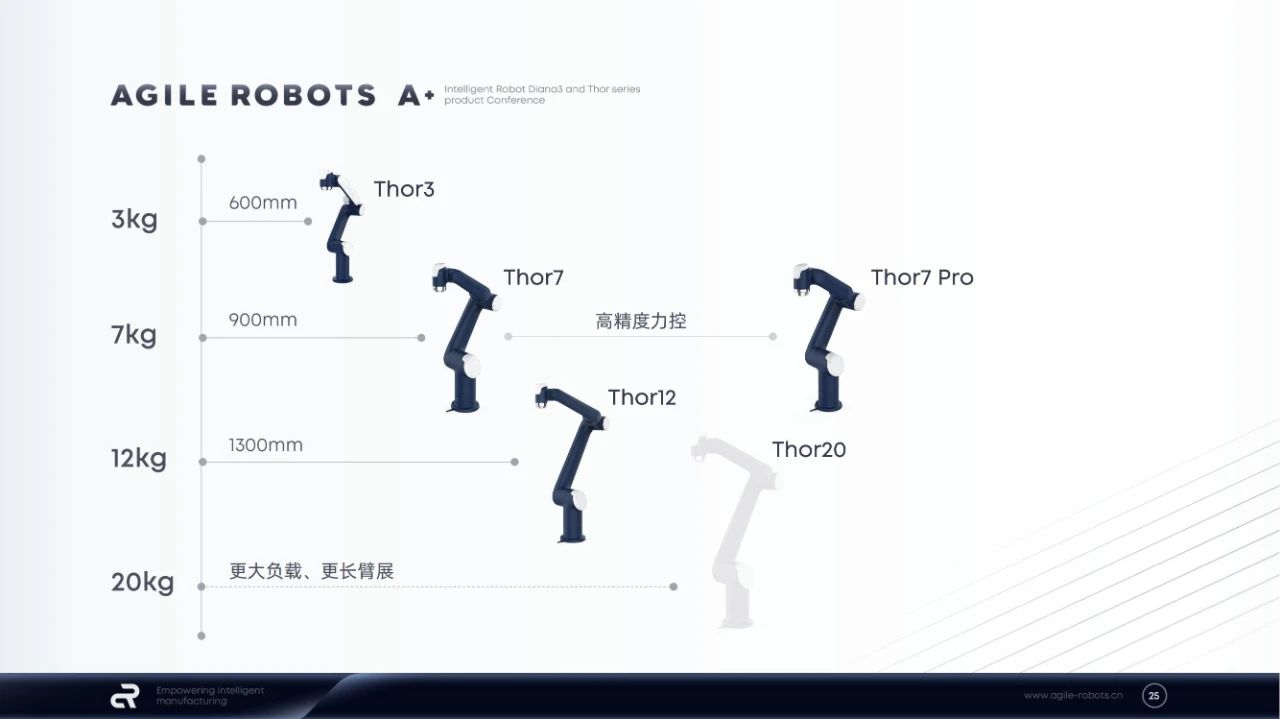

Recently, Agile Robots has further expanded its Diana and Thor series families, launching five intelligent robots that cover a wider range of fields, providing customers with more choices and higher performance. Intelligent robots include Diana 3 from the Diana family, Thor 3 from the Thor family Thor7、Thor7Pro、Thor12, Suitable for a load range from 3kg to 12kg, with a working radius from 600mm to 1300mm, it can provide users with more diverse choices, meet the needs of different task scenarios, and help users achieve automated operations and improve work efficiency.

Equipped with joint force control design

7 degrees of freedom Diana 3 can achieve more precise control

Diana 3 is a seven degree of freedom robot that can mimic the movements of the seven joints of the human arm - the shoulder, elbow, and wrist - and has the ability to complete multi angle and multi-directional work in complex environments. It also has IP54 level dust and water resistance. All joints of Diana 3 are designed with modularity, which helps shorten the development cycle and reduce research and development costs. Compared with common six degree of freedom robots, seven degree of freedom robots have more degrees of freedom in motion, allowing for more complex and precise posture transformations and motion trajectories. They can also flexibly avoid singularities, navigate obstacles, and complete various complex tasks in narrow spaces or unstructured environments.

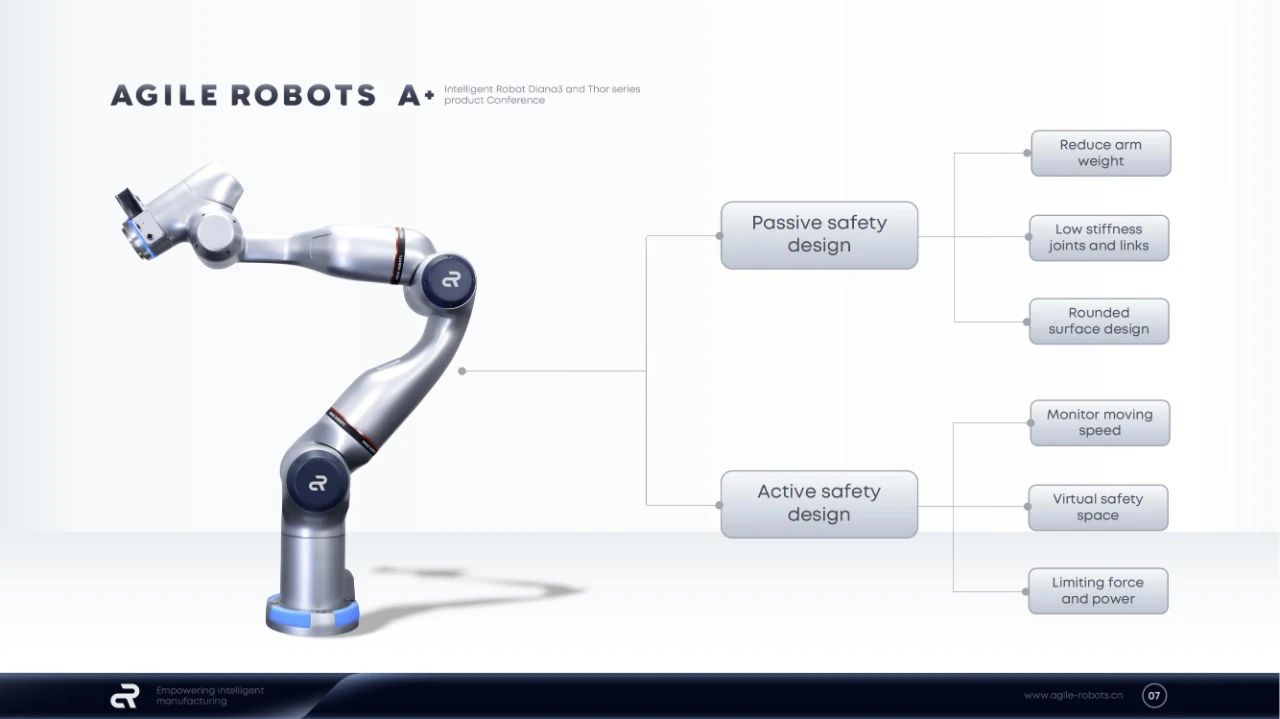

In terms of core technology, Diana 3 is equipped with joint force control technology, which can accurately perceive and control the torque applied by each joint in motion, allowing the robot to have more sensitive tactile feedback and achieve more accurate force control. In addition, it can freely adjust the controlled force according to different task modes to meet the needs of differentiated application scenarios.

In the Diana 3 released this time, Agile Robots will add its self-developed intelligent robot operating system AgileCore to it. There is no need to develop complex programming plans, just inform the robot of the tasks it needs to complete, and the robot will autonomously generate execution steps to complete the next operation process, greatly improving work efficiency. Therefore, Diana 3 is not only suitable for manufacturing, but also for commercial service scenarios.

The best solution for compact space

Thor series makes it easier to adapt to small workspaces

In fields such as 3C electronics manufacturing and automotive manufacturing, intensive multi station task applications are commonly used. Ordinary robots find it difficult to perform in limited and narrow spaces, while industrial assembly lines are difficult to adjust in terms of length and density. This greatly tests the robot's ability to operate flexibly in narrow spaces at the end.

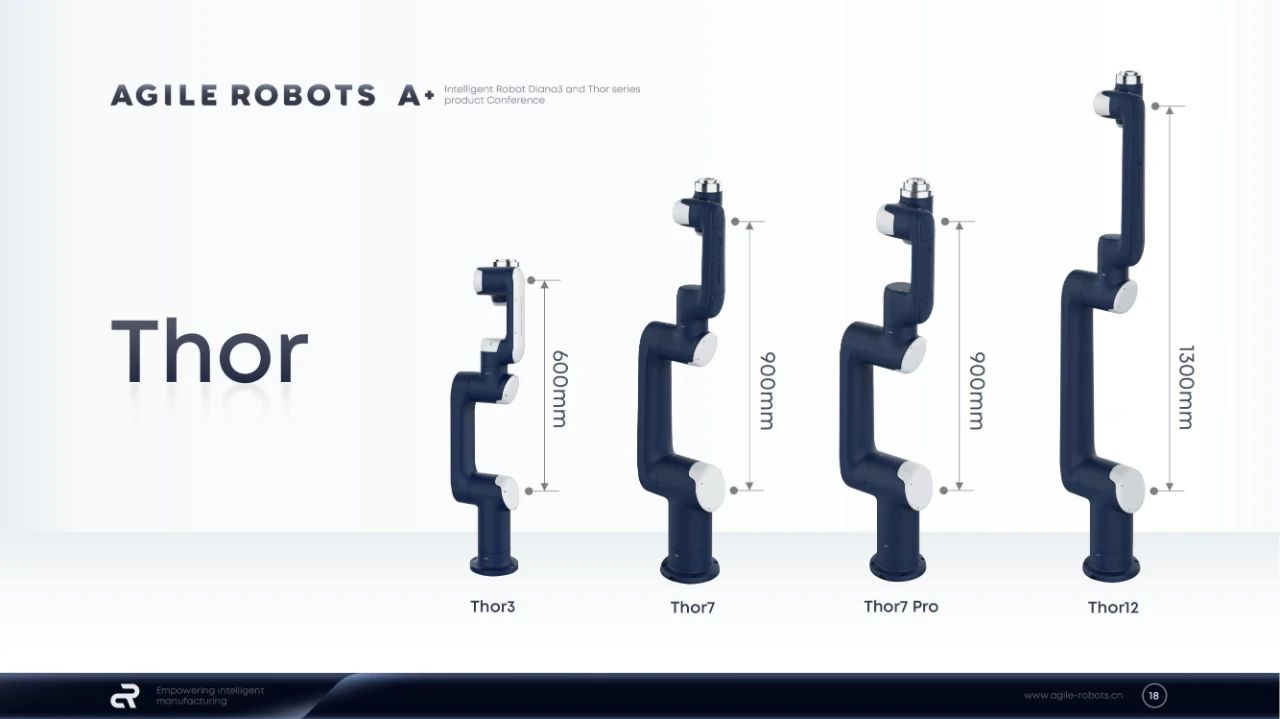

To meet the needs of compact industrial environments, Siling has launched four new products in the Thor series, including Thor3, Thor7, Thor12, and high-precision force control Thor7 Pro. It covers the needs of light and medium loads and different arm spans, and is suitable for various application scenarios.

In terms of load-bearing capacity, the Thor3 robot is designed for small assembly scenarios, with a 3kg load capacity, smaller size, and more flexible operating space. It can be easily placed on a desktop for use. Thor7 can meet a load capacity of 7kg, with a wider range of application scenarios, suitable for loading, unloading, assembly and other processes. In terms of heavy loads, Siling has also launched the Thor12 robot, which has a high load capacity of 12kg and a longer arm extension range, and has comprehensive application capabilities in handling, assembly, and palletizing.

In order to meet the needs of compact and high-precision production scenarios such as polishing, fine assembly, and constant force control, the Thor series has undergone a comprehensive upgrade and launched the Thor7 Pro product. The biggest feature of this product is that it is equipped with 6-degree-of-freedom joint force control technology, which has a smaller self weight and small diameter base, occupies a smaller area, and can be quickly and flexibly arranged in compact scenarios. In terms of performance, the TCP speed of Thor7 Pro can reach up to 2.5m/s, and it is equipped with a high-precision torque sensor, making its accuracy reach the 0.5N level. In addition, the Thor7 Pro is equipped with variable damping and stiffness to meet different polishing and assembly task scenarios. In terms of safety, Thor7 Pro is equipped with highly sensitive collision detection and motion control intelligent algorithm capabilities, which can achieve ultimate safety and sensitive perception.

In terms of compact space and large load, the Thor series will also launch the Thor20 product in the future, which meets the requirement of 20kg large load and is suitable for higher load assembly line scenarios such as handling and palletizing.

The release of Diana 3 and Thor series effectively solves the problem of precise force control in the fields of 3C electronic manufacturing, automotive manufacturing, and other intensive multi station robot collaboration and complex task processing. In segmented differentiated scenarios, Siling robots will better empower intelligent manufacturing.