两倍300.jpg)

两倍300.jpg)

两倍300.jpg)

- FIP

- Diana 7

- Diana 7 Med

- Thor 3

- Thor 7

- Thor 7 Pro

- Thor 12

- Thor20

- AMR

-

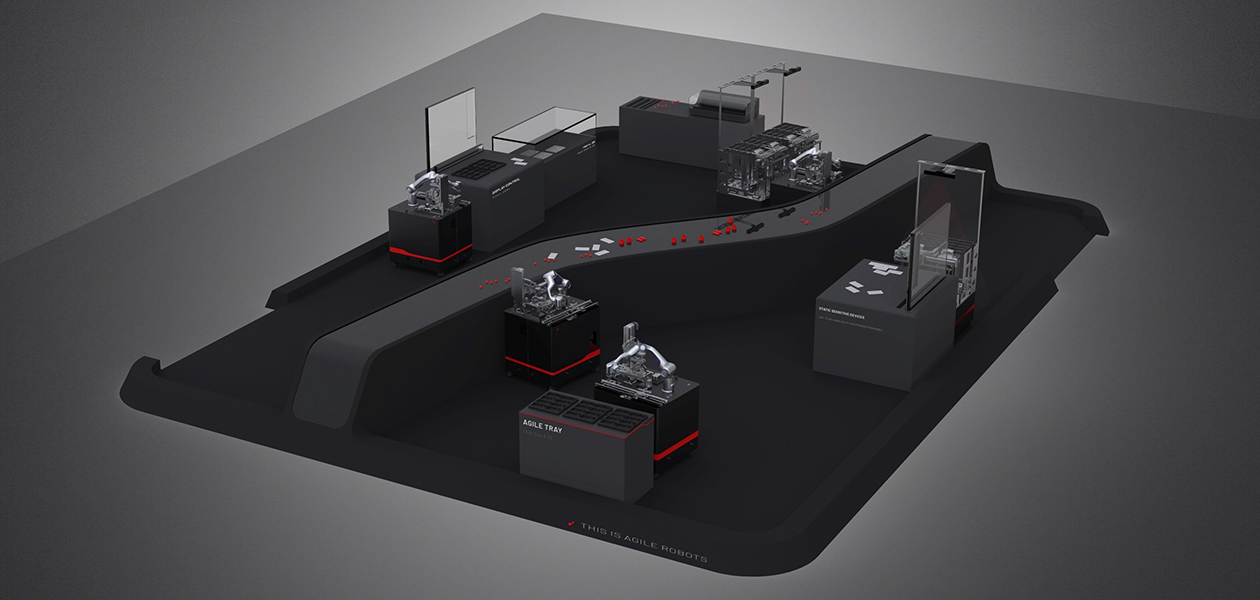

FIPFlexible Intelligent Platform (FIP) consists of universal intelligent robot operation platform, modular conveyor belt and intelligent feeding system. It can quickly adapt to different types of production lines through rapidly replaceable modular end tools and platform tooling. With the self-developed Agile Core operating system, FIP can upload new skills, program tasks, change and adjust new production line layout to realize flexible intelligent production, shorten the deployment time significantly and reduce the difficulty and costs for the system integrations.

-

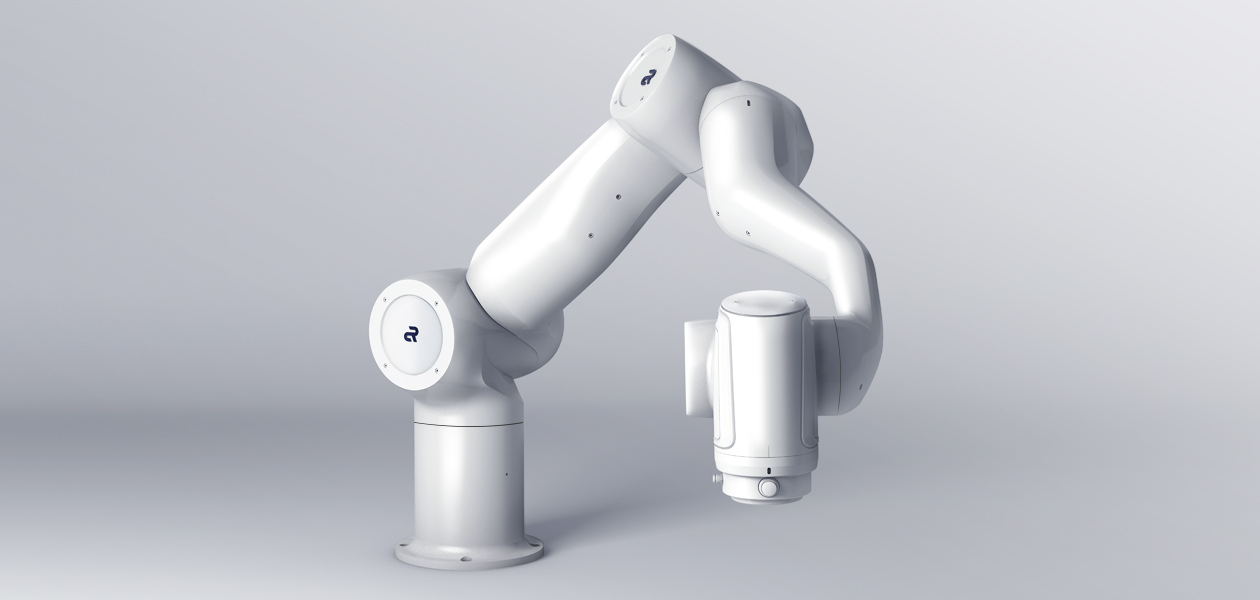

Diana 7Diana 7 is a high-precision intelligent force control robot independently developed by Agile Robots, with high-precision torque sensors built into the joints and highly sensitive force sensing and collision detection capabilities. The 7 degree of freedom design improves the flexibility of the robot. The zero-space control technology enables the robot to avoid obstacles flexibly in the limited workspace, so it can easily adapt to more complex application scenarios.

-

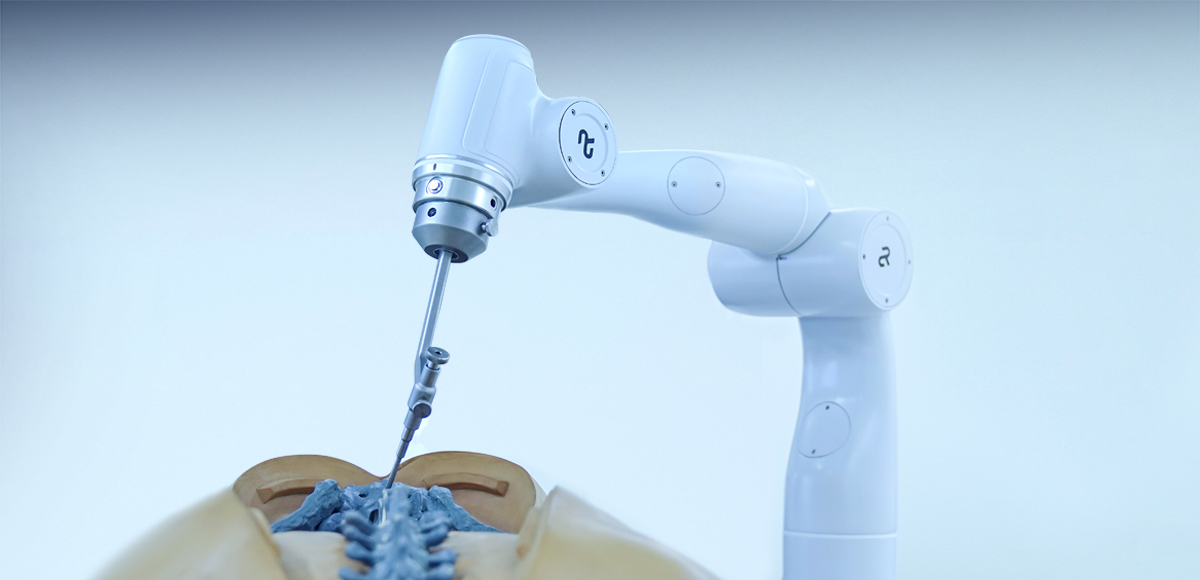

Diana 7 MedDiana 7 Med is a universal medical robot independently developed by Agile Robots, with high-precision torque sensors built into the joints and highly sensitive force sensing and collision detection capabilities. With 7 degrees of freedom design, it has flexible working space and control mode. The main application scenarios include: orthopaedical, neurosurgery, dentistry and other hard tissue robot-assisted surgery, in addition to ultrasound-related diagnosis and treatment, rehabilitation physiotherapy etc.

-

Thor 3Thor3 is a high-precision intelligent robot developed by Agile Robots, with functions such as safe collision detection and graphical programming. It is small, light, agile, easy to operate and quick to install, suitable for applications such as light assembly and automated workstations, and can easily achieve rapid deployment of work scenarios and safe interaction with the surrounding equipment and environment.

-

Thor 7Thor7 is a high-precision intelligent robot independently developed by Agile Robots. Equipped with safe collision detection and graphical programming capabilities, it has a load capacity of 7kg and a working radius of up to 900mm. Thor7 is characterized by its easy operation, agility, and quick deployment, making it suitable for scenarios such as automated integration, assembly, and loading and unloading. Furthermore, it can safely interact with surrounding equipment and the environment.

-

Thor 7 ProThor7 Pro is a high-precision intelligent force controlled robot developed by Agile Robots. Equipped with safety collision detection, joint torque control, drag teaching and graphical programming. Allows for rapid deployment and easy adaptation to multiple application scenarios. Built-in high-precision joint torque sensor enables high-precision force sensing and torque control. Enables secure, real-time interaction with peripherals and the environment.

-

Thor 12Thor12 is a high-precision intelligent robot developed by Agile Robots, with functions such as safe collision detection and graphical programming. It has a maximum load of 12kg and a working radius of up to 1300mm.Featuring fast working, easy operation and quick deployment, it is suitable for assembly, loading and unloading, handling and palletizing. It meets the demands of high-tempo operations and enables safe interaction with peripheral equipment and the environment.

-

Thor20Thor20 is a high-precision intelligent robot developed by Agile Robots. It has a maximum load of 20kg and a working radius of up to 1700mm, and a protection rating of IP54. Easy to operate and quick to deploy, with safe collision detection and graphical programming features. Mainly used in assembly, loading and unloading, handling and palletizing. Able to meet the needs of large load operation.

-

AMRAMR350-01 fully automatic composite robot simulates manual walking and operation, suitable for recognition, picking and placing, detection and other scenarios. Through the large-scale autonomous movement of composite robots and the flexible operation of robotic arms and machine vision, it meets various needs of factories, such as automatic material handling, loading and unloading, distribution, storage and transportation on production lines. It has been widely used in industries such as 3C electronics and semiconductor packaging. The fully automatic composite robot uses modular design to make one device versatile and improve production efficiency.

-

World Leading Force Control TechnologyWith self-developed powerful AI algorithm and high-resolution torque sensor, Agile Robots achieves the world's most sensitive collision detection capability. Agile Robots secure absolute safety of the human body via collision detection technology with millisecond-level response time and powerful computing power in the events such as the knife tip touches the human skin. Agile Robots is committed to breaking through the limits of the existing robot technology to make the robotic perception more sensitive.

-

Intelligent Robot Operating SystemAgile Robots provides world leading robotic brain and operating system (Agile Core) that are continuously evolving and iteratively upgraded to form an ecosystem of software and hardware integration. Such ecosystem redefines the configuration mode of automation system that integrate with force control and visual control functions. Agile Core is compatible to huge number of intelligent software and hardware, carrying out rapid and intelligent deployment to improve the equipment utilization rate significantly.

-

Autonomous Planning & Robot IntelligenceThe self-developed AI algorithm based on deep and reinforcement machine learning which achieves millisecond-level visual recognition speed and realizes autonomous robot path planning. The robot brain enables robots to quickly identify massive unknown object targets and automatically identify grabbable parts to make man-machine collaboration more convenient, efficient and safe.

-

World Class Machine Vision AlgorithmWith our profound accumulation in visual perception technology, Agile Robots let the robot "see the world". Agile Robots independently developed key technologies include high-precision sensor calibration, feature extraction, matching and tracking, target detection and case segmentation based on deep learning. The deployment is simple, reliable and can support parallel acceleration. It can realize accurate, stable and rapid object positioning, measurement and space pose calculation. The Agile Machine Vision Technology can be applied to vision guided robot trajectory generation, trajectory correction, visual servo and other scenes to meet the operating needs of robots in unknown and unstructured scenes. The Agile Machine Vision Technology has been applied in various industries, including but not limited to consumer electronics manufacturing industry, medical related industries, agriculture and animal husbandry, light industry manufacturing etc.

Agile Robots holds the first educational workshop for teachers and students

On the 10th and 11th of October, Agile Robots welcomed 80 students of the 3rd grade and 10 teachers from Munich International School into its headquarters for the first educational workshop. The artificial intelligence and robotics start-up located in Munich and Beijing aims to spark the interest of the younger generation in robotics, and to offer an immersive experience for them to envision infinite possibilities of the future with robots. To demonstrate the capabilities of the intelligent robots, the team of Agile Robots set up a series of seven stations, including applications with Diana 7, an AMR (Autonomous Mobile Robot), and the Educational Web App. By simply clicking on the tablet, the children learned how to code and control the movement of the robots.

Read more

10.31

两倍300.jpg)

两倍300 拷贝 .jpeg)

两倍300 .jpg)